Automation Advances- Revolutionizing Manufacturing Automation

Exploring Robotics, AI, and IoT in Manufacturing Automation Manufacturing automation is undergoing a rapid transformation, driven by technological advancements that promise to revolutionize the industry. This article delves into the latest innovations in manufacturing automation, covering essential technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT). We will explore how these […]

Exploring Robotics, AI, and IoT in Manufacturing Automation

Manufacturing automation is undergoing a rapid transformation, driven by technological advancements that promise to revolutionize the industry. This article delves into the latest innovations in manufacturing automation, covering essential technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT).

We will explore how these advancements are driving efficiency, enhancing operational precision, and reducing downtime in manufacturing processes. Additionally, we will examine the benefits of automation, including cost savings, improved quality control, and faster production times, and provide insights into future trends and implementation strategies for industrial automation.

Cutting-Edge Technologies in Manufacturing Automation

Exploring Robotics, AI, and IoT in Manufacturing Automation

The integration of robotics, AI, and IoT is at the forefront of manufacturing automation. Robotics has transformed assembly lines with precision and speed, capable of performing complex tasks that were once deemed impossible for machines. AI enhances these capabilities by enabling machines to learn from data, make decisions, and optimize processes without human intervention. The IoT connects these intelligent machines, creating a network of devices that communicate and coordinate with each other to streamline operations.

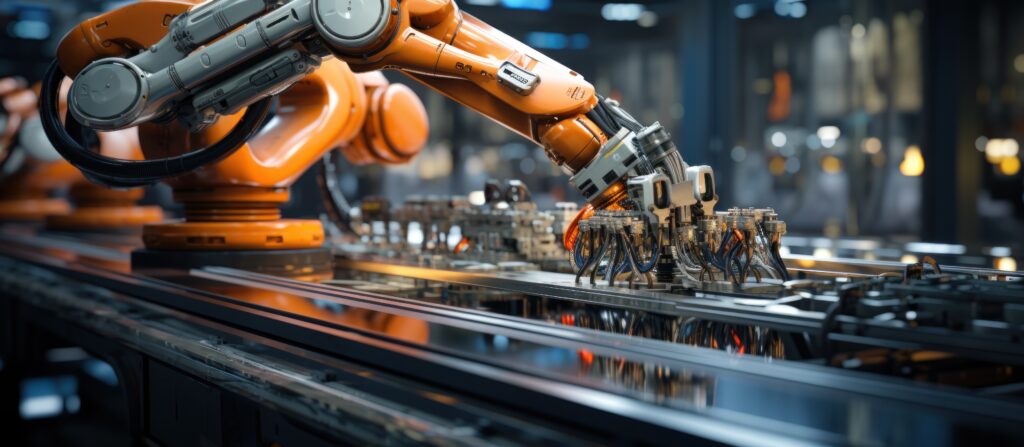

Robotics: Enhancing Precision and Efficiency

Robotic systems in manufacturing automation have significantly improved precision and efficiency. Robots can work tirelessly without fatigue, ensuring consistent quality and reducing human error.

Advanced robotic arms and automated guided vehicles (AGVs) are now commonplace in factories, handling tasks ranging from welding and painting to assembly and packaging. These robots are equipped with sensors and vision systems, allowing them to adapt to different tasks and environments, further boosting productivity.

Artificial Intelligence: Driving Smart Manufacturing

AI is a game-changer in manufacturing automation. Machine learning algorithms analyze vast amounts of data to identify patterns and optimize processes. Predictive maintenance, powered by AI, can foresee equipment failures before they occur, reducing downtime and maintenance costs. AI-driven quality control systems inspect products in real-time, detecting defects that are imperceptible to the human eye, thus ensuring high-quality standards are met consistently.

The Internet of Things: Creating Connected Factories

The IoT connects machines, sensors, and devices within a factory, creating a cohesive and intelligent network. This connectivity allows for real-time monitoring and control of manufacturing processes. IoT-enabled devices collect data on various parameters such as temperature, humidity, and machine performance, providing valuable insights for optimizing production. Smart factories utilize IoT to enhance operational efficiency, improve energy management, and ensure safety standards.

Smart Factories and Automated Assembly Lines

Transforming Manufacturing with Smart Factories: Smart factories represent the pinnacle of manufacturing automation. These facilities leverage robotics, AI, and IoT to create highly efficient and flexible production environments.

In smart factories, machines and systems communicate with each other autonomously, adjusting operations in real-time to meet demand fluctuations. This level of automation minimizes human intervention, reduces errors, and maximizes throughput.

Automated Assembly Lines: Revolutionizing Production

Automated assembly lines are a cornerstone of modern manufacturing. These lines consist of interconnected machines and robots working in harmony to assemble products with minimal human involvement.

Automated assembly lines are highly adaptable, capable of switching between different product configurations quickly. This flexibility is crucial in today’s market, where customization and rapid response to consumer demands are key competitive advantages.

Advanced Process Control Systems: Optimizing Operations with Advanced Process Control Systems

Advanced process control (APC) systems play a vital role in manufacturing automation. These systems use data from sensors and feedback loops to regulate manufacturing processes, ensuring optimal performance.

APC systems can adjust variables such as temperature, pressure, and flow rates in real-time, maintaining product quality and consistency. By continuously monitoring and adjusting operations, APC systems enhance efficiency and reduce waste.

Benefits of Manufacturing Automation: Cost Savings through Efficiency and Productivity

One of the most significant benefits of manufacturing automation is cost savings. Automated systems increase production speed and efficiency, allowing manufacturers to produce more with less. This reduction in labor costs, combined with higher output rates, translates to substantial savings. Additionally, automation minimizes material waste and reduces energy consumption, further contributing to cost-effectiveness.

Improved Quality Control and Consistency

Automation ensures consistent quality control across manufacturing processes. AI-driven inspection systems detect defects and anomalies in real-time, enabling immediate corrective actions.

This level of precision is challenging to achieve with manual inspection. As a result, manufacturers can maintain high-quality standards and reduce the risk of recalls or defective products reaching the market.

Faster Production Times and Market Responsiveness

Automated manufacturing processes are inherently faster than manual ones. Robotics and AI enable continuous production without the need for breaks, significantly reducing production times. This speed allows manufacturers to respond quickly to market demands and shorten time-to-market for new products. The ability to scale production up or down rapidly is a critical advantage in today’s dynamic market environment.

Future Trends in Industrial Automation: Exploring Emerging Technologies in Manufacturing Automation

The future of manufacturing automation is bright, with several emerging technologies poised to further revolutionize the industry. One such technology is collaborative robots, or cobots, designed to work alongside human workers.

Cobots enhance productivity by combining human dexterity with robotic precision. Additionally, advancements in AI and machine learning will enable even more sophisticated predictive analytics and decision-making capabilities.

Adopting Green Manufacturing Practices

Sustainability is becoming a priority in manufacturing automation. Green manufacturing practices focus on reducing environmental impact through energy-efficient processes and waste reduction.

Automation plays a crucial role in achieving these goals by optimizing resource usage and minimizing emissions. Future trends in industrial automation will likely see increased adoption of eco-friendly technologies and practices.

Implementing Manufacturing Automation Solutions: Steps to Successfully Implement Automation in Manufacturing

Implementing manufacturing automation requires careful planning and execution. The first step is to conduct a thorough assessment of current processes to identify areas that can benefit from automation.

Next, manufacturers should invest in the right technologies, such as robotics, AI, and IoT devices, tailored to their specific needs. Training the workforce to work alongside automated systems is also crucial to ensure a smooth transition.

Overcoming Challenges in Automation Implementation

While the benefits of manufacturing automation are clear, there are challenges to consider. High initial costs and the complexity of integrating new technologies with existing systems can be daunting.

Additionally, the shift to automation may require reskilling the workforce to adapt to new roles. However, with a strategic approach and investment in training, these challenges can be effectively managed.

Manufacturing automation is transforming the industry, driven by advancements in robotics, AI, and IoT. Smart factories, automated assembly lines, and advanced process control systems are enhancing operational precision, reducing downtime, and improving efficiency. The benefits of automation, including cost savings, improved quality control, and faster production times, are compelling.

As the industry continues to evolve, adopting emerging technologies and green manufacturing practices will be key to staying competitive. By understanding and implementing these automation solutions, manufacturers can unlock their full potential and thrive in today’s fast-paced market.